➡️ Introduction

Rework and waste are two of the most damaging forms of inefficiency in any project. They consume time, inflate costs, drain morale, and undermine stakeholder confidence. In many industries — especially construction, IT, engineering, and operations — rework can account for 5% to 15% of project costs, and waste can delay delivery by weeks or months.

Top 5 Project Management Software

Preventing rework and waste requires more than fixing mistakes — it requires building systems that ensure clarity, alignment, quality, and continuous improvement.

This guide explains the root causes of rework and waste, and outlines practical steps that project managers can use to eliminate them before they disrupt delivery.

✅ What Causes Rework and Waste?

Understanding the root causes helps project managers design effective prevention strategies.

Common causes include:

✔️ unclear requirements

✔️ last-minute changes or scope creep

✔️ poor communication

✔️ low-quality workmanship

✔️ unvalidated assumptions

✔️ missing quality standards

✔️ lack of stakeholder alignment

✔️ insufficient testing or reviews

✔️ inefficient workflows

✔️ skill gaps or inadequate training

Rework and waste rarely come from a single mistake — they accumulate from multiple weak points in the project system.

✅ Why Preventing Rework and Waste Matters

Effective prevention leads to:

✔️ faster delivery

✔️ reduced costs

✔️ higher team productivity

✔️ fewer delays

✔️ improved customer satisfaction

✔️ better-quality deliverables

✔️ stronger team reputation

Teams that eliminate waste gain a competitive advantage, especially in fast-moving environments.

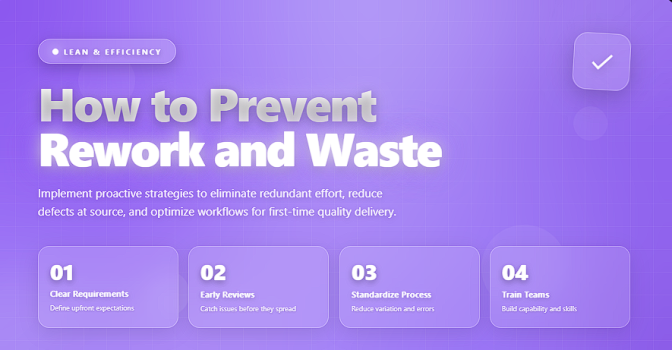

✅ How to Prevent Rework and Waste (Step-by-Step)

✔️ 1. Start With Clear, Verified Requirements

Many defects originate from unclear or misunderstood requirements.

Project managers should:

- document detailed requirements

- validate them with stakeholders

- create acceptance criteria early

- eliminate assumptions

- ensure all requirements are traceable

Clear requirements = fewer surprises later.

✔️ 2. Strengthen Change Control

Uncontrolled scope changes create massive rework.

Implement a strict change management process:

✔️ assess impact before approving

✔️ require justification and sponsor sign-off

✔️ update schedule and cost baselines

✔️ communicate the change clearly to the team

Controlled changes protect the team from chaotic rework.

✔️ 3. Use Standardized Processes and Templates

Standardization reduces variation — one of the primary causes of waste.

Use templates and processes for:

- documentation

- scheduling

- design

- testing

- quality review

- reporting

Consistency prevents mistakes and keeps the team aligned.

✔️ 4. Implement Quality Checks Early and Frequently

Quality must be built in — not inspected at the end.

Project managers should encourage:

✔️ peer reviews

✔️ design walkthroughs

✔️ technical evaluations

✔️ regular testing cycles

✔️ early defect detection

The earlier an issue is caught, the cheaper and easier it is to fix.

✔️ 5. Improve Team Communication

Miscommunication is one of the primary reasons rework happens.

Ensure that:

✔️ requirements are understood

✔️ decisions are documented

✔️ tasks are clarified

✔️ expectations are aligned

✔️ teams use the same communication channels

Clear communication = fewer errors and fewer misunderstandings.

✔️ 6. Invest in Training and Skill Development

Skill gaps create waste and rework.

Provide training on:

- tools and software

- technical skills

- quality assurance practices

- process improvements

- Lean and Six Sigma principles

Investing in people reduces long-term risks.

✔️ 7. Use Checklists for Critical Tasks

Checklists ensure consistency and prevent avoidable errors.

They are especially important for:

✔️ design reviews

✔️ safety checks

✔️ testing

✔️ stakeholder approvals

✔️ handover processes

Simple checklists prevent expensive mistakes.

✔️ 8. Build Buffer Time for Quality Work

Projects with unrealistic schedules create rushed work → rushed work leads to defects → defects lead to rework.

Add reasonable buffer time to:

✔️ quality assurance activities

✔️ reviews

✔️ testing

✔️ pilot runs

Quality must be scheduled — not squeezed.

✔️ 9. Analyze Data to Identify Patterns

Capture and study project data to uncover recurring sources of rework:

- defect logs

- customer complaints

- test results

- cycle time variations

- rework hours

Data reveals hidden inefficiencies and guides continuous improvement.

✔️ 10. Apply Lean and Six Sigma Concepts

Lean helps eliminate waste (time, motion, defects).

Six Sigma helps reduce variation and improve consistency.

Both methodologies support:

✔️ process optimization

✔️ better quality

✔️ reduced defects

✔️ prevention-focused culture

Together, they form a powerful foundation against rework and waste.

❌ Common Pitfalls to Avoid

❌ assuming “small” errors won’t matter

❌ rushing deliverables without QA

❌ approving unclear requirements

❌ ignoring stakeholder feedback

❌ failing to update documents after changes

❌ skipping testing due to time pressure

These mistakes compound and create substantial downstream rework.

⭐ Best Practices for Sustainable Prevention

✔️ make quality a team responsibility

✔️ document decisions immediately

✔️ use visual workflows (Kanban, boards, dashboards)

✔️ hold frequent alignment sessions

✔️ create a culture of asking questions early

✔️ implement lessons learned after each milestone

Preventing waste is not a one-time effort — it’s a mindset.

⭐ Final Thoughts

Rework and waste are silent project killers.

They drain time, budget, and energy — and often appear only when it’s too late.

But with the right processes, communication, and quality mindset, project managers can dramatically reduce them.

The best projects succeed not by working harder,

but by eliminating the work that shouldn’t have been done at all.