➡️ Introduction

Control does not come from plans.

It comes from understanding deviation.

Top 5 Project Management Software

Many projects track performance diligently, yet still lose control because differences between plan and reality are acknowledged but not interpreted. Numbers are reported, variances are noted — and nothing changes.

Variance analysis exists to close that gap.

Used properly, variance analysis transforms raw performance data into actionable insight. Used poorly, it becomes a historical record of missed opportunities.

This article explains what variance analysis really is, how to use it for effective control, and how project managers can turn variance signals into timely decisions.

✅ What Variance Analysis Really Means

Variance analysis compares what was planned with what actually happened to understand:

✔️ where deviation occurred

✔️ how significant it is

✔️ whether it is improving or worsening

✔️ what corrective action is required

Variance itself is not the problem.

Unexplained variance is.

✅ Why Variance Analysis Is Central to Control

Projects are dynamic systems.

Without variance analysis:

✔️ issues are discovered late

✔️ trends are missed

✔️ corrective actions are reactive

✔️ accountability is unclear

With variance analysis:

✔️ deviations surface early

✔️ root causes are explored

✔️ decisions are evidence-based

✔️ control becomes proactive

Control is about response, not punishment.

✅ Core Variance Types for Project Control

What to track — and why each variance matters.

| Variance Type | What It Compares | Why It Matters |

|---|---|---|

| Schedule Variance | Planned vs actual progress timing | Reveals delivery slippage early |

| Cost Variance | Planned vs actual spending | Shows efficiency and budget risk |

| Scope Variance | Approved vs delivered work | Prevents uncontrolled expansion |

| Resource Variance | Planned vs actual capacity usage | Detects overload and burnout risk |

| Quality Variance | Expected vs actual defect levels | Signals unsustainable compression |

✅ Interpreting Variance Correctly

Variance numbers alone do not tell the story.

Effective interpretation requires:

✔️ understanding root causes

✔️ distinguishing one-off events from trends

✔️ assessing impact on final outcomes

✔️ correlating variances across dimensions

For example:

Schedule variance caused by a known, resolved issue is very different from variance driven by systemic overload.

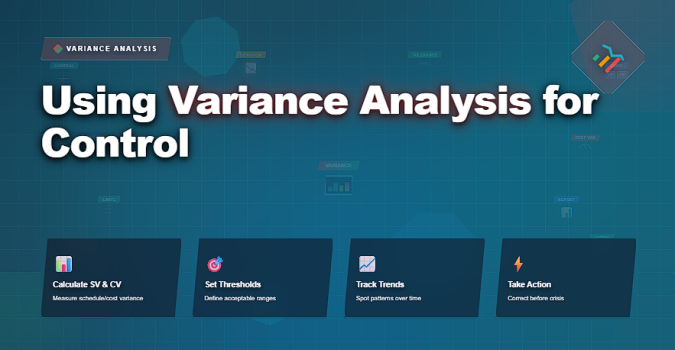

✅ Turning Variance into Control Actions

Control only exists when variance leads to action.

Project managers should:

✔️ define acceptable variance thresholds

✔️ investigate causes early

✔️ decide whether to correct, absorb, or escalate

✔️ adjust plans deliberately

✔️ track whether actions reduce variance

Unacted variance is simply delayed failure.

❌ Common Mistakes in Variance Analysis

❌ tracking variance without thresholds

❌ focusing on explanation instead of correction

❌ reacting to every small deviation

❌ ignoring persistent minor variances

❌ using variance as a blame tool

❌ reporting numbers without recommendations

Variance analysis should guide — not punish.

⭐ Best Practices

✔️ define control limits clearly

✔️ track trends, not snapshots

✔️ review variance regularly

✔️ connect variance to decisions

✔️ integrate variance analysis into governance routines

✔️ focus on forward-looking impact

⭐ Final Thoughts

Variance analysis does not exist to prove a plan was wrong.

It exists to keep delivery aligned with reality.

Strong project managers use variance analysis as an early warning system — detecting deviation, understanding causes, and acting while flexibility still exists.

Projects succeed not because variance never occurs —

but because it is analyzed, understood, and controlled in time.