➡️ Introduction

Six Sigma is one of the most powerful methodologies for achieving process excellence, reducing defects, and improving customer satisfaction. Although it began in manufacturing, today Six Sigma is used in IT, construction, healthcare, finance, operations, supply chain, and project management.

Top 5 Project Management Software

For project managers, Six Sigma offers data-driven decision-making, structured problem-solving, and predictable performance improvements.

Whether you’re leading Agile teams, PMO environments, or organizational change, understanding Six Sigma gives you a competitive edge in delivering higher quality with fewer errors and lower costs.

This article explains Six Sigma in simple terms — what it is, why it matters, and how project managers can use it daily.

✅ What Is Six Sigma?

Six Sigma is a data-driven, process improvement methodology that aims to reduce variation and minimize defects.

The name “Six Sigma” refers to achieving a performance level where processes produce no more than 3.4 defects per million opportunities (DPMO) — an extremely high standard of quality.

Six Sigma is built on three pillars:

✔️ Customer focus

✔️ Data-driven decisions

✔️ Continuous improvement

It uses structured problem-solving techniques such as DMAIC and DMADV.

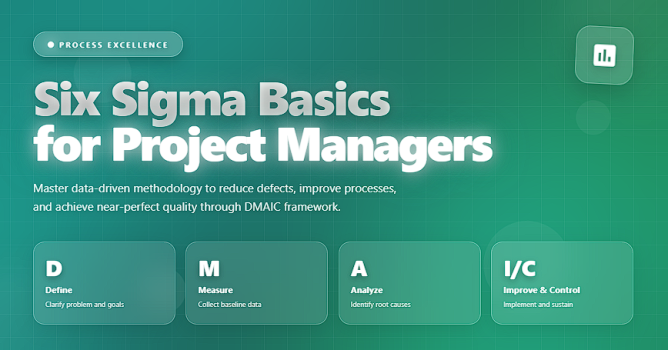

✅ The DMAIC Framework (Core of Six Sigma)

DMAIC is the most widely used Six Sigma method. It is ideal for improving existing processes.

✔️ 1. Define

Clarify the problem, scope, stakeholders, and project goals.

Project managers create a project charter, identify customers, and define success metrics.

✔️ 2. Measure

Collect data to understand current performance.

This step answers: How is the process performing today?

✔️ 3. Analyze

Identify the root causes of the problem.

Tools include:

- Fishbone diagram

- Pareto analysis

- Root cause analysis

- Regression analysis

✔️ 4. Improve

Develop and test solutions.

This step includes piloting, risk analysis, and process adjustments.

✔️ 5. Control

Maintain the improvements over time.

Project managers use:

- control charts

- SOP updates

- monitoring dashboards

- training plans

DMAIC ensures improvements stick and prevent backsliding.

✅ The DMADV Framework (For New Process Design)

DMADV is used when you are creating a new process or redesigning a broken one.

The steps are:

✔️ Define

✔️ Measure

✔️ Analyze

✔️ Design

✔️ Verify

Project managers use DMADV for:

- new product development

- new workflows

- major system redesigns

- digital transformation projects

✅ Key Six Sigma Tools Every Project Manager Should Know

Here are high-impact tools used daily in Six Sigma projects:

✔️ Pareto Chart

Shows which causes contribute most to defects (80/20 rule).

✔️ SIPOC Diagram

Maps Suppliers, Inputs, Process, Outputs, and Customers.

✔️ Control Charts

Monitor process variations over time.

✔️ Process Mapping

Visualizes process steps to identify gaps or inefficiencies.

✔️ FMEA – Failure Mode & Effects Analysis

Identifies risks, severity, and likelihood of failure.

✔️ Voice of Customer (VoC)

Captures customer needs and expectations.

✔️ 5 Whys

Simple method for root cause identification.

✔️ Fishbone (Ishikawa) Diagram

Maps root causes across categories such as People, Methods, or Materials.

Project managers who master these tools reduce rework, increase efficiency, and improve predictability.

✅ How Six Sigma Supports Project Managers

Six Sigma strengthens project management in these ways:

✔️ Better Decision-Making

Replaces guesswork with data-driven insights.

✔️ Clearer Problem Solving

DMAIC and DMADV provide structure for tackling complex issues.

✔️ Stronger Quality Control

Six Sigma reduces defects, delays, and unexpected rework.

✔️ More Efficient Execution

Removes waste and streamlines workflows.

✔️ Improved Customer Satisfaction

Produces consistent, reliable, and predictable results.

✔️ Cross-Functional Alignment

Six Sigma tools enhance communication across teams and departments.

Project managers who adopt Six Sigma principles deliver faster, cleaner, and more reliable projects.

❌ Common Misconceptions About Six Sigma

❌ “Six Sigma is only for manufacturing.”

→ Today it’s used in IT, business, HR, healthcare, and more.

❌ “Six Sigma is too technical.”

→ Most tools are simple and practical for any PM.

❌ “Six Sigma slows the project down.”

→ It prevents rework and accelerates delivery.

❌ “Six Sigma equals perfection.”

→ It means predictable, stable processes, not perfection.

⭐ Best Practices for Project Managers Using Six Sigma

✔️ Start with one problem — don’t try to apply every tool at once.

✔️ Use DMAIC as your default improvement method.

✔️ Leverage data instead of assumptions.

✔️ Collaborate with stakeholders early.

✔️ Document every change for long-term control.

✔️ Integrate Six Sigma with Agile and Lean tools when appropriate.

⭐ Final Thoughts

Six Sigma is not just a quality framework — it is a strategic mindset.

By focusing on data, eliminating variation, and improving processes, project managers can deliver better outcomes with fewer defects and more predictable performance.

Great project managers don’t just complete tasks —

they continuously improve how work gets done.